PLAYFINITY

DEVELOPING

PRODUCTS

I have developed several products through the years in Playfinity where I have performed the complete work of designing, prototyping, testing, engineering and implementing the products for mass production. Here i will give some insights to some of the processes and tasks done to give an insight to my capabilities within product development.

INTRODUCTION

We founded the company on making the infrastructure for creating active gaming. The first product to make was the SMART activity tracker. This universal activity tracker unit was the hardware to connect gear to our software infrastructure, PlayOS, and gaming apps. By inserting it into sport gear, the gear would be enable to be gamified.

When designing this central unit for our ecosystem of products, the goal was to create an iconic design for the brand. Another driver was to have a form that could provide play on is own enabling simple gamification; Roll, slide on one side, friction slide on other, stand on edge, bump softly off surfaces, hang on things and hook onto snaplocks. A third important factor for design, was to enable multiple ways to fasten unit to gear.

Skill sets: Design, Multiple use design, System design, Engineering for robustness and waterrisistance. Modeling for injection molding, Two component injection mold, Mechanisms to fulfill toy certification, design for integrating electronics

THE SMART

The first playware, the function unit the activity tracker would enter into, was the Smart Ball. The strategy was to start the journey of introducing active gaming to the market with a universal toy, the ball for throw and catch. With this, a range of gaming scenarios could be developed.

With this first playware, “Speedy ball”, we aimed for a fastening mechanism for easy snap function for entering and ejecting activity tracker. This to emphasis that the tech being easily shifted from one play unit to another. Buying other balls such at the “Squeezy” or “Bounce” play units with different ball characteristics, you would only have to buy the less expensive playware, and not have to buy the more costly tech unit, the activity tracker. This system would give the costumer flexibility in his purchase, as well as provide us with only one tech plattform to maintain. The environmentally aspect to this is that recycling would be easy, and it opened for shifting the the business model to a subscription model down the road, where the activity tracker would be returned when subscription was ended.

Skill sets: Design, System design, Strategic design for business model, Over molding PU foam on plastic core mechanism. Engineering for durability and waterrisistance

THE

SMART BALL

Learnings from launching the smart ball was that it is difficult to sell something this innovative to the market. Gaming outdoors intrigued the market, but still left them with many questions; What is active gaming? What is an orange ball? How does this fit into my life? Thus, to take down the level of newness, we aimed to make a ball that was recognisable, that used our existing detections for throw and catch, and that already had a large user base, Baseball and Softball.

Designing the baseball requires a major focus on durability. I redesigned the core, and had to make a screw fastening for lid. By constructing a robust injection molded core with integrated TPR parts and metal hinge insert, we had a system for making super robust balls for various sizes. We prototyped double overmolded PU solutions for the core to obtain more flexibility in regards to surface quality and weight. The end result was great. One durability test was pitching the ball 300 times as hards as we can into a concrete wall. Ball was fine, as well as the tech being connected through the whole process. We have had a set of 12 balls at a baseball camp in the US with many thousands of kids playing with the ball for two years. All still working with no issues.

Skill sets: Design, Engineering for durability and water resistance, Injection molding, Overmolding with PU, system design,

THE GAMING BASEBALL

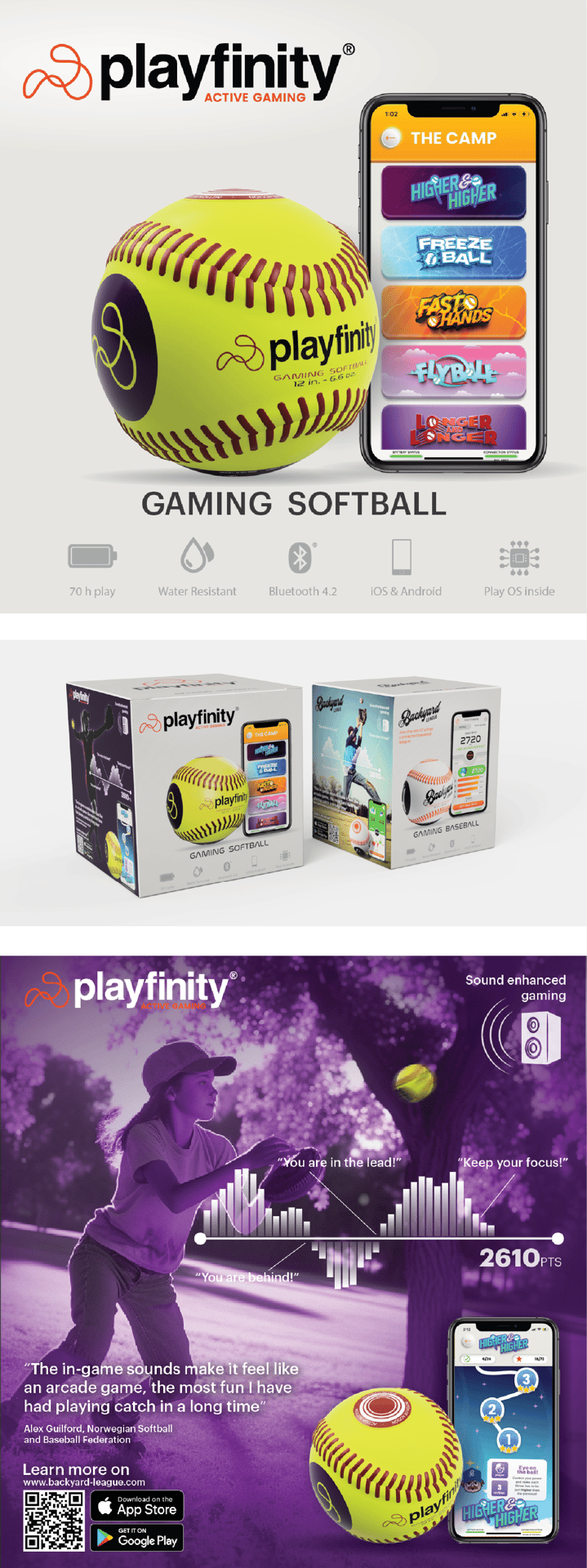

With the system design fondation from the baseball, developing the following softball was a quick and cost efficient process. The work consisted of adjusting the TPR part for the button function to right height and finding the right PU formula to achieve regulation surface and weight for the product. Having the system for weight adjustment with set screws benefited process greatly.

Worked on design on ball to create product family identity, and make room for solutions when obtaining partnerships (co-branding), and making future ball suitcases for team purchases (identifying different balls).

Develop packaging, building on product family. Used AI to create imaging for packaging.

Skill sets: System design, Design for product family, Branding, AI imaging with Midjourney

THE GAMING SOFTBALL

We had prototyped making a football based on the production methods from baseball. How ever, We wanted to enter the market with a products that actually was the real thing. Football being the major sport in the world, we knew this would be an amazing business opportunity. Hence started the process of new manufacturing partners and processes, along with developing a new technology platform for integration into bladder balls.

Another motivation for investing in developing the football was based on learnings from our previous products. Experiences that demanded more than one player narrowed the usage of the product. Being able to provide more one player experiences, like our trampoline product, would vastly help or user retention.

Hence started a long challenging development process with many tours to the worlds home of football production, Sialkot Pakistan.

Skill sets: Product roadmap strategy, Analytic thinking, Recruiting new manufactures

GAMING FOOTBALL

THE OPPORTUNITY

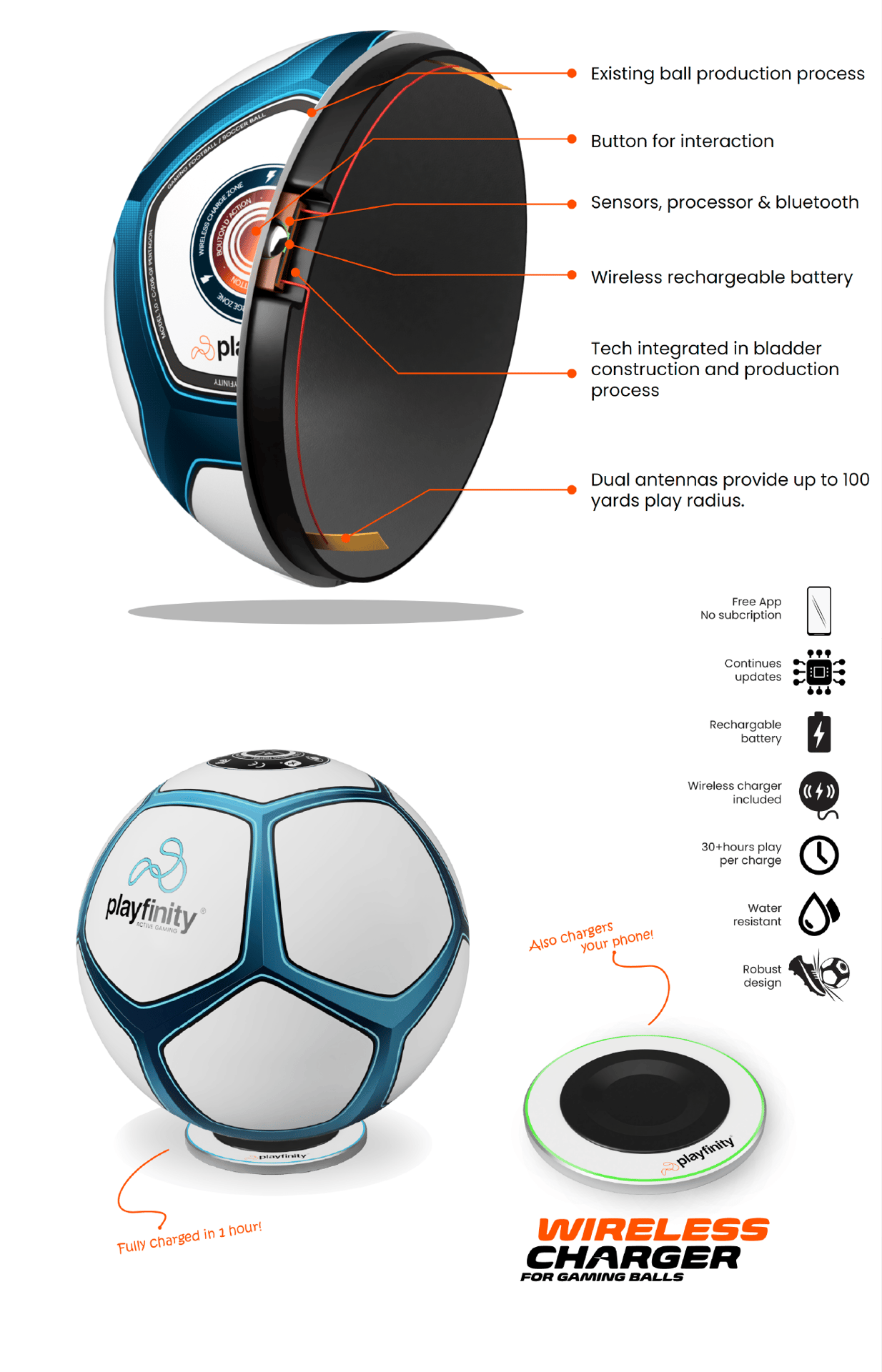

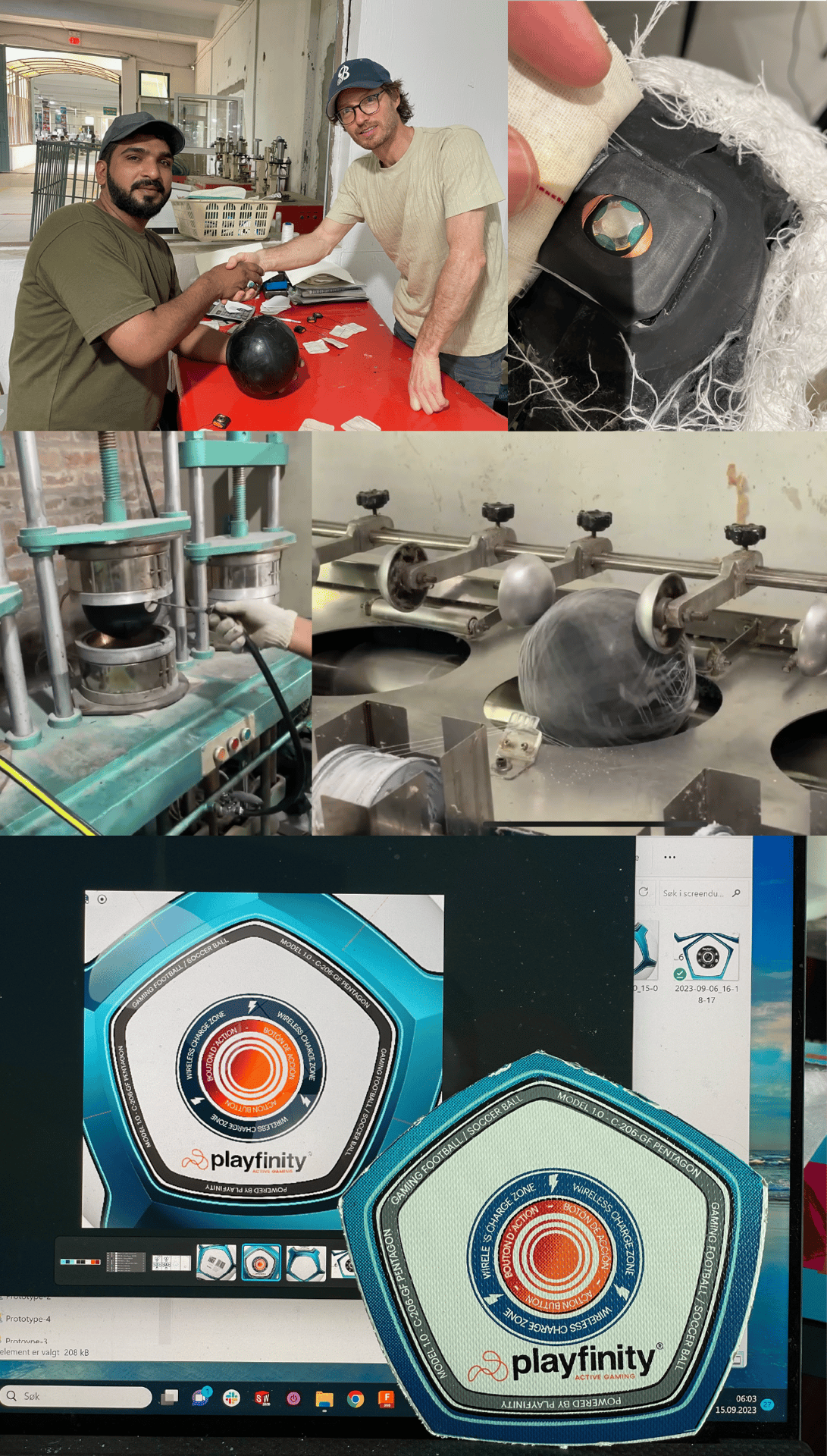

Many tests and iterations were done to find the right method for integrating our tech into an inflatable ball. The main challenge having a well functioning button on the ball surface, whilst protecting our tech from extreme forces and adding minimal weight. In parallel we had to develop a completely new technology platform with induction charging as well as antenna technology for obtaining omni uniform signal strength.

Skill sets: Product development, Technology development

DEVELOPING THE GAMING FOOTBALL

The result of development, in close collaboration with production workers at the factories, was making a pocket into the bladder walls. From this we defined the right configuration of electronic components and how to assemble these for football production obtaining right durability, button function (sound and tactile feedback), and fixation for durable performance in a flexible environment.

One particular challenge was getting the tech placed correctly under the graphics of the ballskinn. +/- 3 mm was the tolerance, and for this production process was really a challenge. The manufacturer, not believing this could be done, ended up saying; “You have shown us that anything is possible”. An important factor for success was my making of a retrofitted system of molding tools for bladder production, as well as challenging production to adjust method for entering bladder into ball skin.

Skill sets: Communication and collaboration with production workers, Understanding production, Gaining trust, Developing production tooling

UNDESTANDING PRODUCTION GAMING FOOTBALL

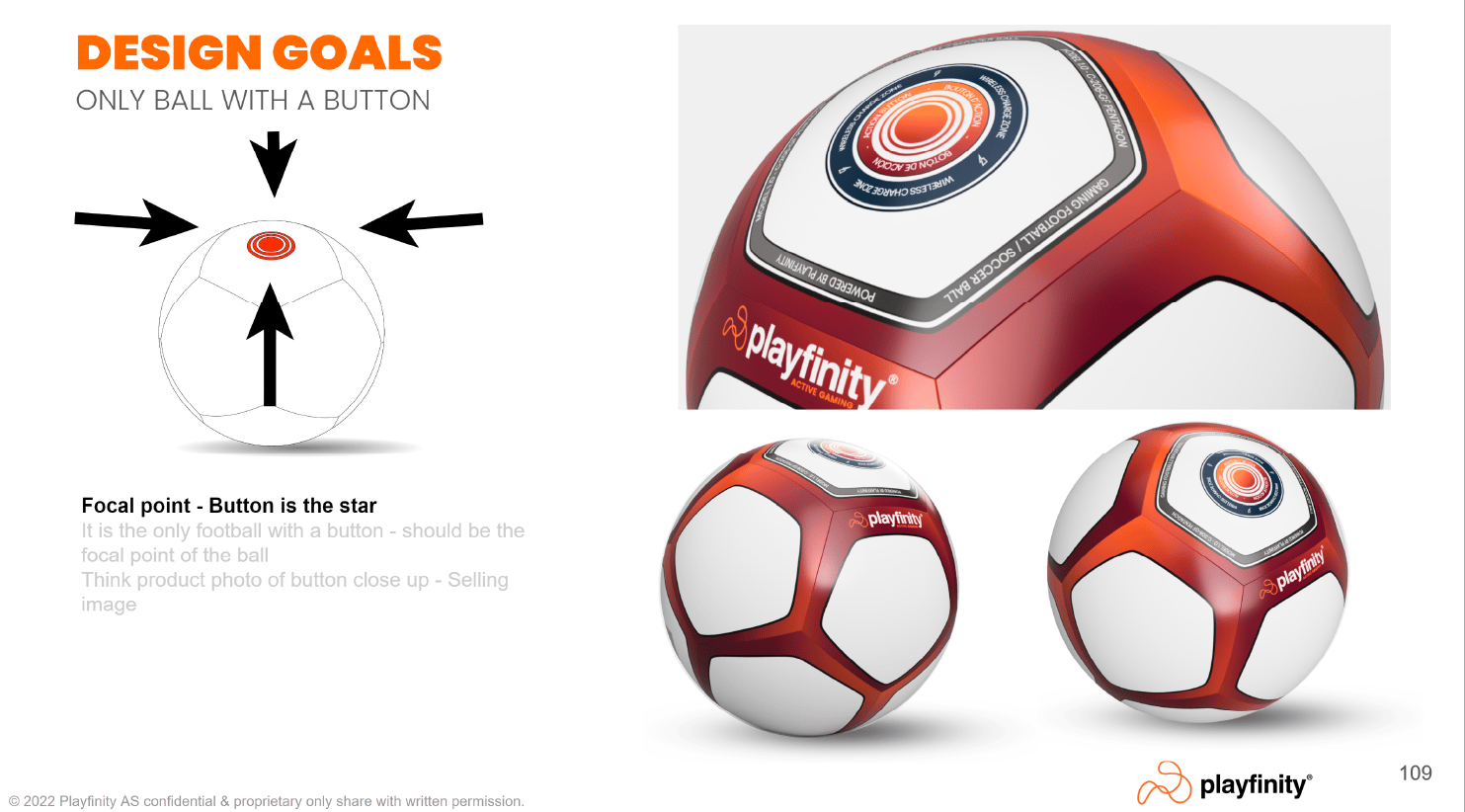

Making a design on a sphere is a challenge. The industry has specialists on the task, but given our early stage economy, I had to figure out this myself. After finding a precise method of converting a design from a 2D production template from factory to a 3D model for rendering, I could start the design process. Hence started the process of defining the goals for th design and making concepts that would work on a spherical ball even with minor offsets between patches.

Main design goals were amongst; emphasising the button area, provide direction toward button to quickly find it when holding the ball, and creating identity for the ball differentiating it from the vast amount of ball designs on the market.

Skill sets: Design identity, Graphic design, 3D visualisation, Creating printing foundation for production, Communication

PRODUCT GRAPHICS

GAMING FOOTBALL

PRODUCTION

We wanted to packaging to emphasise the gaming football as something new on the market; It was the first football in the world with a button, the first gaming football.

Researching the solutions that existed, and hearing the learnings from our manufacturer. I ended up making my own die-cut solution for packaging. The button would be presented for customers to explore, as well as providing enough surfaces to promote the product as well as space to integrate wireless charger and adapter. Getting a production efficient packaging, good protection for ball and accessories, stiff construction and easily assembly was the design task performed.

Skill sets: Package design and production, Graphic design, Retail insight, Die-cut construction, Branding and communication

PACKAGE DESIGN

GAMING FOOTBALL

"The mind can be convinced, but the heart must be won" Simon Sinek